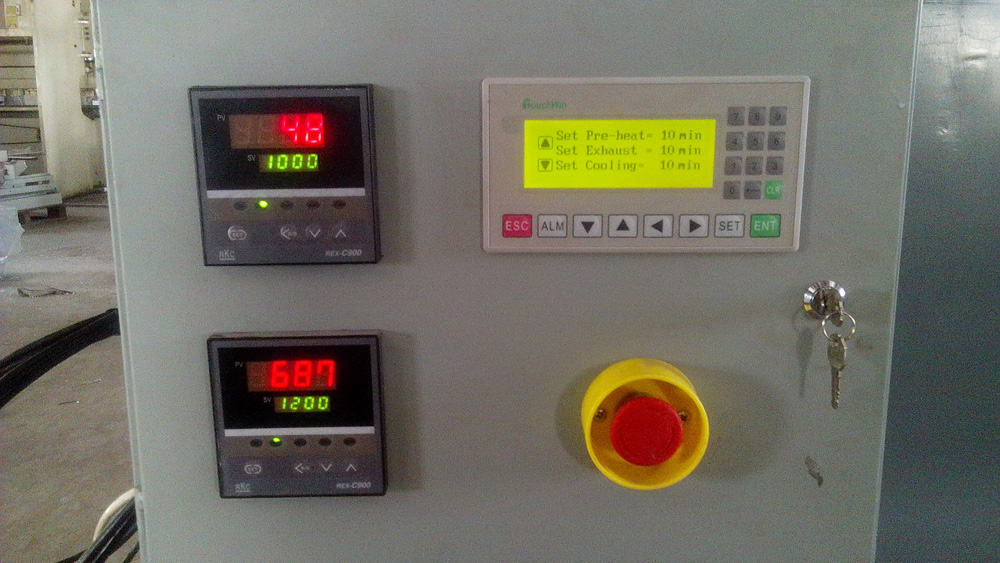

An incinerator represents a complete solution to the problem of disposal of all hospital waste types. The liquid fuel is diesel. The incinerator should meet the environment standards. Expected Technical specifications The incinerator shall be fully self contained. The incinerator plant shall incorporate a control panel for its operation. On the control panel we shall have a visual display of the chamber temperatures. This visual display must control and monitor the incinerator and his performance. Capacity of destruction in weight shall be 60 Kg/h. It should be able to operate not less than 10 hours/day This incinerator must be able to destruct all combustible wastes produced by hospitals, private clinics, laboratories, institutes, etc… Design Specification : Types A, B, C, D, and E of medical waste “PYROLYTIC” combustion, by controlling the gasification of waste. The incinerator must avoid the release of black smoke and fine dust, during the loadings. It shall be able to reduce the volume of wastes by 98%. It shall be able to hold emission in the second burn with gas residence of not less than 2 seconds. The incineration should be completely free from visible smoke as well as offensive odours. 1.0The primary ignition burner shall providing ignition of the waste to 850 °C and must switch off to conserve fuel. The primary combustion chamber shall be constructed from heavy steel plate and the unit is internally lined with a complete layer of hote face refractory and high efficiency insulation. The Internal diameter of the Chimney at least: Ø 400 and its height: 8 m The Volume of the combustion chamber at least: 1.200 L The Dimension of the door for loading in cm at least: 70×70. Burner operation should be Automatic On/Off Fuel : diesel Manufacturer to provide necessary information for the best of the installation

An incinerator represents a complete solution to the problem of disposal of all hospital waste types. The liquid fuel is diesel. The incinerator should meet the environment standards. Expected Technical specifications The incinerator shall be fully self contained. The incinerator plant shall incorporate a control panel for its operation. On the control panel we shall have a visual display of the chamber temperatures. This visual display must control and monitor the incinerator and his performance. Capacity of destruction in weight shall be 60 Kg/h. It should be able to operate not less than 10 hours/day This incinerator must be able to destruct all combustible wastes produced by hospitals, private clinics, laboratories, institutes, etc… Design Specification : Types A, B, C, D, and E of medical waste “PYROLYTIC” combustion, by controlling the gasification of waste. The incinerator must avoid the release of black smoke and fine dust, during the loadings. It shall be able to reduce the volume of wastes by 98%. It shall be able to hold emission in the second burn with gas residence of not less than 2 seconds. The incineration should be completely free from visible smoke as well as offensive odours. 1.0The primary ignition burner shall providing ignition of the waste to 850 °C and must switch off to conserve fuel. The primary combustion chamber shall be constructed from heavy steel plate and the unit is internally lined with a complete layer of hote face refractory and high efficiency insulation. The Internal diameter of the Chimney at least: Ø 400 and its height: 8 m The Volume of the combustion chamber at least: 1.200 L The Dimension of the door for loading in cm at least: 70×70. Burner operation should be Automatic On/Off Fuel : diesel Manufacturer to provide necessary information for the best of the installation

INCINERATEUR DE DECHETS HOSPITALIER SPECIFICATIONS TECHNIQUES.Capacité destructive de 55 Kg/h jour de déchets hospitaliers avec un p .c. i jusqu’à 3.200 Kcal/Kg1)Type de déchet hospitalier2)Pouvoir calorifique inférieur 3.200 kcal/kg3)Humidité 20%4)Teneur en cendres et/ou inertes 8%5)Capacité destructive nominale 55 kg/h6)Volume chambre de combustion 1,65 m³7)Volume chambre postcombustion 2.1 m³8)Temps transit des fumées en post combustion /sec. <29)Température minimale en postcombustion 1.100° C10)Teneur d’oxygène libre en postcombustion 6%11)Attribution refuse confectionné en sachets HDPE12)Dispositif de chargement : hydraulique ; capacité de charge 0.5 m³ 13)Combustible prévu Gasoil14)Brûleur en chambre de combustion nbr : 1 15)Brûleur en chambre de postcombustion nbr : 2 • The site is surrounded by an iron fence (sheet metal) 3 meters height from the surface of the earth in order to protect the incinerators from dust storms • The iron fence must have a 5 meters Width gate • Automatic anti-rust and heat electrical circuit must be provided • The furnaces are highly efficient, emissions-free, safe, and environmentally friendly and have capacity of not less than 3,000 kg of materials and the rate of burning at least 400 kg / h• The method of feeding the furnace through a side slot or from the top and the emission of the smoke is completely prevented.• a furnace Must have two rooms, one of them is the main room of not less than the “5” stoves to the process of burning materials and other secondary room of not less “2” stoves to burn resulting gas from the first process as well as the chimney• The main component of the body of the furnace is stainless steel box, the thickness of not less than 7 mm with a layer of zinc phosphate plated with aluminium reflector to heatCONSTITTUTION DE L’APPAREIL.

INCINERATEUR DE DECHETS HOSPITALIER SPECIFICATIONS TECHNIQUES.Capacité destructive de 55 Kg/h jour de déchets hospitaliers avec un p .c. i jusqu’à 3.200 Kcal/Kg1)Type de déchet hospitalier2)Pouvoir calorifique inférieur 3.200 kcal/kg3)Humidité 20%4)Teneur en cendres et/ou inertes 8%5)Capacité destructive nominale 55 kg/h6)Volume chambre de combustion 1,65 m³7)Volume chambre postcombustion 2.1 m³8)Temps transit des fumées en post combustion /sec. <29)Température minimale en postcombustion 1.100° C10)Teneur d’oxygène libre en postcombustion 6%11)Attribution refuse confectionné en sachets HDPE12)Dispositif de chargement : hydraulique ; capacité de charge 0.5 m³ 13)Combustible prévu Gasoil14)Brûleur en chambre de combustion nbr : 1 15)Brûleur en chambre de postcombustion nbr : 2 • The site is surrounded by an iron fence (sheet metal) 3 meters height from the surface of the earth in order to protect the incinerators from dust storms • The iron fence must have a 5 meters Width gate • Automatic anti-rust and heat electrical circuit must be provided • The furnaces are highly efficient, emissions-free, safe, and environmentally friendly and have capacity of not less than 3,000 kg of materials and the rate of burning at least 400 kg / h• The method of feeding the furnace through a side slot or from the top and the emission of the smoke is completely prevented.• a furnace Must have two rooms, one of them is the main room of not less than the “5” stoves to the process of burning materials and other secondary room of not less “2” stoves to burn resulting gas from the first process as well as the chimney• The main component of the body of the furnace is stainless steel box, the thickness of not less than 7 mm with a layer of zinc phosphate plated with aluminium reflector to heatCONSTITTUTION DE L’APPAREIL.

The Incinerator Plant is output wastes incineration from Different petrochemical units. In this project we want to incinerate all output wastes from petrochemical units and also produced high pressure steam from incinerator plant heat generated.At first output waste from petrochemical collects and transfers to transit and sorting center in various forms. Input feeds of incinerator plant are shown in below table: Waste streams of petrochemical unit collect and store in Transit and Sorting Center.In Transit and Sorting Center one laboratory must be considered.In this center, waste will be classified in two groups:– Unsuitable for burning– Suitable for burningUnsuitable waste for burning can be divided into the 4 categories:– Buried materials– Materials (wastes) that need to be stabilized before buried– Materials (wastes) that can be sold.– Wastes that can be returned to petrochemical.Suitable wastes are classified into the two categories:– Input wastes to rotary kiln, consist of solids and waste fluids.– Input wastes to static kiln, consist of clean fluids and gasses.All solid wastes must be transferred to storage pit from Transit and Sorting Center. Solid wastes storage pit is input of rotary kiln.All fluid wastes must be stored and stabilized in Transit and Sorting Center. All storage and stabilization devices or facility must be considered. Storage and stabilization devices (facility) consist of:Tanks, Pumps (Transfer, Loading & Unloading), Agitator (Mixer), Blanketing System, Flare system, Instrumentation and Control Systems, etcStorage and stabilization capacity must be considered based on worst case (shut down).Generally incinerator plant consists of two similar trains (capacity of each train is 100%). Each train consists of a rotary kiln and a static kiln.Based on client request, efficiency of incinerator plant is 99.8% for all components and for aromatic must be higher than that amount.Please be attention, produce high pressure steam from output heat of incinerator plant is in this scope of work.