SECONDARY CHAMBER TECHNICAL SPECIFICATIONS FOR CIPDR INCINERATOR OF 75 KGS/HR CAPACITY A. INCINERATOR 1. Brand Type & Model: “ALFA-THERM” Oil Fired Incinerator Model BMWC-100 or approved equivalent. 2. Burning Capacity: 75 kgs/hr or more 3. Auxiliary Fuel: Diesel OR Industrial Diesel Oil 4. Type of Burner Operation: Mono-block fully automatic burners 5. Temperature: Primary Chamber 800 + 500C & Secondary Chamber 1050 + 500C B. PRIMARY CHAMBER 1. Type: Static Solid Hearth 2. Material of Construction: Mild Steel 6mm 3. Refractory thickness: 115mm thick 4. Material: Refractory bricks 5. Temperature resistance: 14000C 6. Insulation thickness: 115mm thick 7. Material: Insulation bricks 8. Waste Charging: Manual 9. Ash Removal: Manual 1. Type: Static Solid Hearth 2. Material of Construction: Mild Steel 6mm 3. Refractory thickness: 115mm thick 4. Material: Refractory bricks 5. Temperature resistance: 14000C 6. Insulation thickness: 115mm 7. Material: Insulation bricks D. EDUCTOR FAN 1. Type: High Pressure Centrifugal type 2. MOC: Mild Steel E. COMBUSTION FAN 1. Type: Centrifugal 2. Modulation: Manual damper control 3. MOC: Mild Steel 4. Drive: Direct drive F. CYCLONE SEPARATOR – AIR POLLUTION CONTROL DEVICE 1. MOC: Mild Steel 2. Internal lining: Refractory lined 3. Collection Port: Provided at the bottom G. CONTROL PANEL 1. MOC: CRCA Sheet 2. Type of temperature controller: Digital 3. Finish & Painting type: Powder coated 4. Audio-visual alarm system: Provided H. BURNERS 1. No. of burners: 2 Nos. (1Nos in primary Chamber and 1No. in Secondary Chamber) 2. Type: Mono-block fully automatic 3. Fuel: Diesel 4. Make: “Alfa-Therm” I. FUEL OIL STORAGE TANK 1. MOC & Capacity: Mild Steel, suitable capacity 2. Other Standard Accessories: Diesel Oil level indicator, piping with valves & N. R. Valve 3. Visual checking of Fuel: Provided

The Model is for up to 300kgs capacity per batch load and will burn at around 55kgs per hour. The unit has top loading design and has a heavy duty refractory cement lining for maximum heat retention. Unit have large top lid for easy loading, and specially designed front ash door, for ash removal. This unit operates at over 1100°C in the primary chamber to ensure complete combustion. This model also benefits from a heavy duty secondary chamber and burner which ensures a complete re-burn of any smoke and emissions and a 0.5 second gas retention time. PRIMARY CHAMBER Heavy-duty steel casing High quality refractory lining and insulation Large full size top load door and liquid retention sill 1 x diesel oil fired ignition burners operated on/off SECONDARY CHAMBER Heavy-duty steel casing High quality refractory lining and insulation 1 x diesel oil fired ignition burners operated on/off CHIMNEY Heavy-duty stainless steel casing 1.5m length 0.6m refractory lined stack CONTROL PANEL Control of 1 burner Timer control 0- 12 hours Integral fan timer control Temperature Monitoring Thermostatic Control Automatic Control Cycle time set up ANCILLARIES Operating and maintenance manuals Spares list CONTAINERISATION incinerator fully installed inside of 10 ft ISO certified container 3,5 kwA electricity generator, 1000 litres fuel tank Incinerator mounted on the silenblock cushion.

HIGH TECH PYROLYTIC MEDICAL WEST INCINERATOR 1.Capacity of destruction in weight: 60Kg/h 2.It should be able to operate not less than 10 hours/day. 3.This incinerator must be able to destruct all combustible wastes produced by hospitals, private clinics, laboratories, institutes, etc.. 4.Design Specification: Types A, B, C, D and E of medical waste 5.“PYROLYTIC” combustion by controlling the gasification of waste. 6.The incinerator must avoid the release of black smoke and fine dust, (smokeless) during the loadings. 7.It should be able to reduce the volume of wastes by 98% 8.It should be able to hold emission in the second burn with gas residence of not less than 2 seconds. 9.The incineration should be completely free from visible smoke as well as offensive odours. 10. The lower calorific power (L.C.P) of this waste will be 3,500 kcal/kg the temperatures of combustion: Minimum will be 850oC and max 1400oC post combustion:>1100oC 11. The internal diameter of the chimney:Ø400 and its height: 8m 12. The volume of the combustion chamber: 1,200L 13. The dimension of the door for loading in cm: 70 x 70 14. Burner operation should be automatic on/off

we made several conversation, during the specification, ordering and delivering of our unit Y50 for university of Dodoma, I were in consultancy side, to make a specifications, and supervising during the installation, the unit is ready on site for installations and hope it will be in good order. This type of INCINERATOR is not common to our country, which will need close attendance and day to day training to user, The good performance of the unit will reflect the good image of your products and company at its large, therefore it will need after sale attendance to the customer/user. Although (Model YD-500) is very good incinerator , but I can not find any things about its filtration and air pollution control equipments in the document you sent. I know that the air pollution control equipments are too expensive, so we need an incinerator like (Model YD-500) plus air pollution control equipments , that it can be cover all of EPA standards about air pollution .

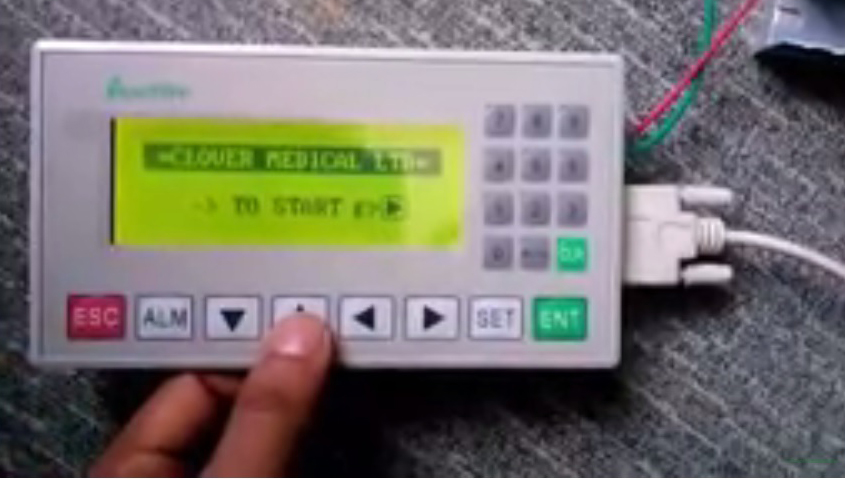

System Capacity: 100 Kg/h Type of Wave: Municipal Waste (Paper, Plastic, Wood etc.) Waste Feeding Manual Fuel: Natural Gas Incinerator Type: Double Chamber External Cladding: MS sheet of suitable gauge, painted with corrosion resistant paint Fuel Gas Emission discharged to the atmosphere should meet Pakistan National Environment Quality Standards (NEQS) User Friendly Operation should be ensured by proper automation. Adequate safety features should incorporated to protect the premises and operators against mishaps and accident. Primary Chamber: Auto on/off Burner Auto temperature control Excess air blower fan. Chamber constructed of two layer refractory lining. Comprising: Thermal insulator lining & Refractory masonry lining, sufficient enough to maintain normal temperature at outside. Secondary Chamber: Auto on/off Burner Auto temperature control Excess air blower fan. The chamber constructed of two layers Refractory Lining. Comprising: Thermal insulator lining & Refractory masonry lining, sufficient enough to maintain normal temperature at outside. Control Panel: Standard PLC control panel Note: All the instruments / controllers must be of high quality, preferably European / Japanese Origin. Chimney / Stack: Made of MS sheet, sufficiently insulated & lined with refractory bricks (where required) to maintain normal temperature at outer surface. Painted with high quality heat & corrosion resistant paint. Note: Provision of Electric Supply & Natural Gas up to incinerator required. Motors of all blowers / fans / pumps must be of high quality, preferably European / Japanese origin. Terms & Conditions: Transportation required for installation point. Installation & commissioning of the whole incinerator system required. Necessary Civil Works / Shed, concrete platform for incinerator and construction of base / pads for stack (if required) are also required.